State Of The Art

Inspection & Processing

What We Offer

Turnkey Inspections, from Data Acquisition Through Reporting

Data Acquisition

Operations

Data Processing

Platform

Analysis

Online

How It Works

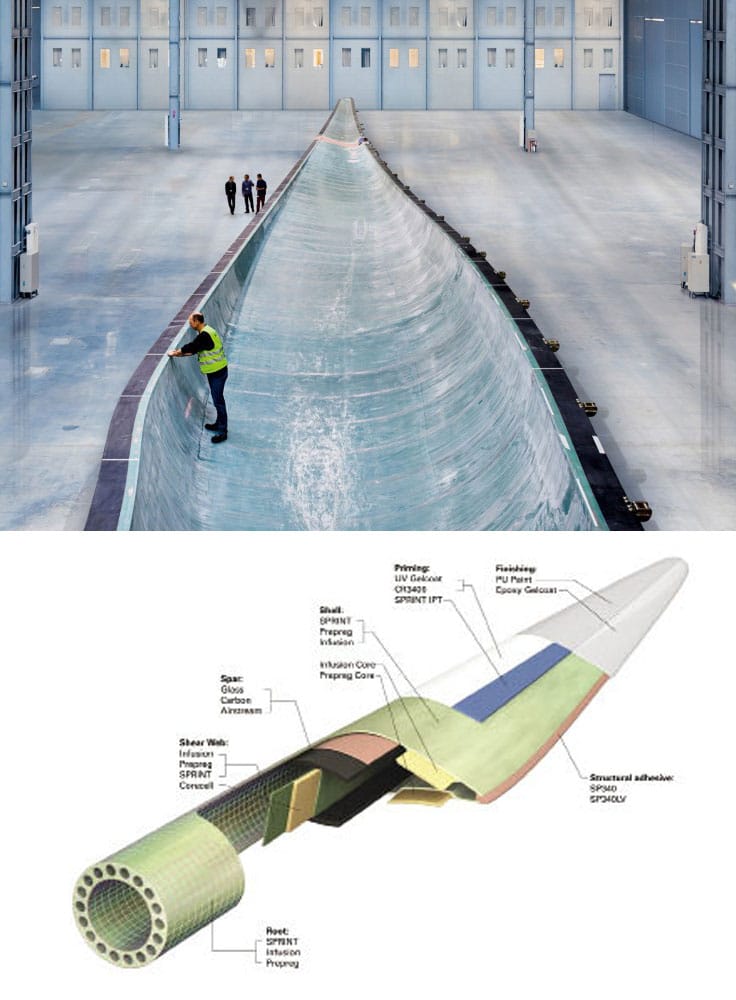

All Inclusive UAV Blades Inspection

We provide our customers a 360° inspection service, from data acquisition to image processing and review highlighting actual defects, areas for future review and major defects requiring immediate action. Helvetis reports provide all.

Experience

10

World Record

20

Track Record

30000

View, Annotate And Report

Cloud analytics &

data management software

The Helvetis Farm Manager acts as a centralised inspection management system allowing users to overview the status of the entire fleet to easily monitor blades health status.

Through our advanced stitching algorithm, Helvetis Farm Manager (HFM) ensures the blade images are merged into a single ultra high-definition image. This can be reviewed by your or our own qualified composite blade experts who will mark up the defects correctly.

Any defects dimensions and locations will automatically be visually reported in a blade report giving your company the immediate actions required to keep your composite blades in good health.

In order to streamline the data management and image review we invented a tailor made image stitching algorithm for the wind industry.

Through the power of Artificial Intelligence and the latest computer vision technologies we’re able to fully automatically merge multiple inspection images in a single high resolution blade photograph.

At Helvetis we can offer fleet wide inspection services that incorporate EOW, Annual, Bi annual and emergency composite blade inspections. With all these services your blade reports we supply to you will be accurate and concise allowing easy decisions to be made.

Helvetis emergency UAV inspections come complete with a composite blade expert at the site to advise you immediately of what you and the UAV pilot are seeing.

Helvetis blade experts are also available for consulting advice on repairs you require or are receiving when you receive your Helvetis blade inspection report. So if your an asset management company, a energy supplier, a private owner or a financial company with an ever expanding wind portfolio at Helvetis we can assist you with the repair your being offered by the blade repair company.

Farm Manager allows your company to either start a new composite blade history or upload previous data to continue with an improved blade lifecycle. Ensuring that you can identify major and minor blade issues across your fleet with immediate reported remedies to act upon.

Get In Touch Now &

Let's Talk About Inspections

Need an inspection? Contact us now for a free consultation!